| Category | Grade | MFI | Density | Major Applications |

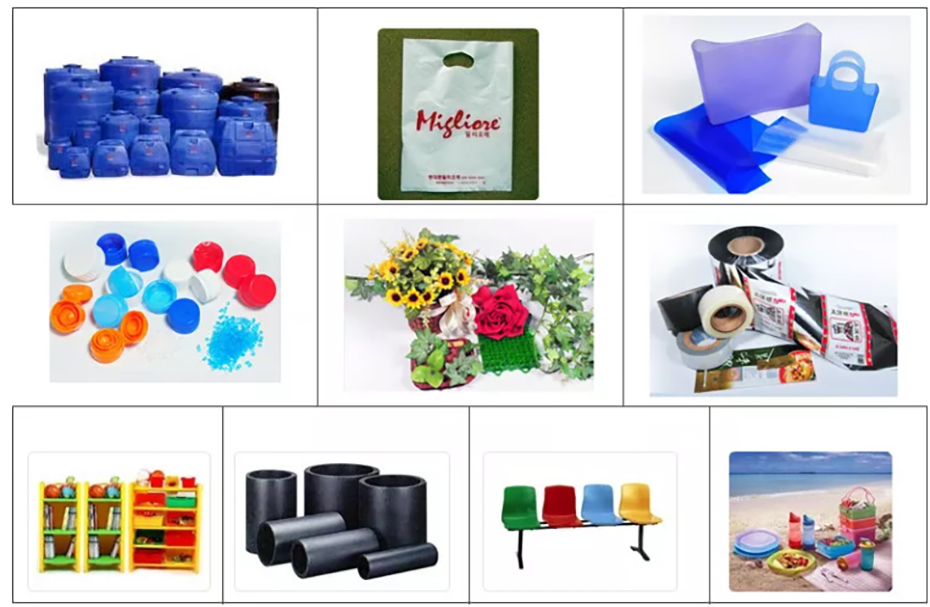

| Homopolymer - Extrusion | F103 | 3.3 | 0.9 | BOPP Film Grade - General Purpose, Lamination & Metallizable films |

| T30S | 3.3 | 0.9 | Raffia Tapes ,Woven Sacks for Packaging Fertilizers, Cement, Polymers, Carpet Backing ,FIBC etc. | |

| T103 | 3.3 | 0.9 | Thermoformed Cups, Containers & Other disposable items | |

| F110 | 11 | 0.9 | TQ and Cast Films for General Purpose Packaging etc. | |

| Homopolymer – Injection Molding | M103 | 3 | 0.9 | General Purpose Injection Molding |

| M106 | 6 | 0.9 | General Purpose Injection Molding | |

| M108 | 8 | 0.9 | General Purpose Injection Molding | |

| M110 | 10 | 0.9 | General Purpose Injection Molding, Furniture etc. | |

| Impact Copolymer – Injection Molding | M304 | 3.5 | 0.9 | Automotive Components, Crates, Pails, Furniture etc. |

| M307 | 7 | 0.9 | General Purpose Injection Molding | |

| M310 | 10 | 0.9 | Battery Boxes | |

| M311T | 10 | 0.9 | Compounding, Automotive Components, Luggage and Industrial Components | |

| M312 | 12 | 0.9 | Compounding, Industrial Components, Automotive Components, Luggage, Pails, Houseware, Sanitary Wares etc. | |

| M315 | 15 | 0.9 | General Purpose Injection Molding | |

| M325 | 25.0 | 0.9 | Compounding, Automotive Components, Houseware, Appliances parts, Extrusion Coating | |

| M340 | 40 | 0.9 | Appliance & White Goods, Automotive component, Compounding,TWIM | |

| Random Copolymer – Blow Molding | B202S | 1.9 | 0.9 | Bottle & Containers for Medical and Transparent Products (e.g. IV Fluid Bottles) etc |

| B200 | 1.9 | 0.9 | General Purpose Blow Molded & Thermoformed Items, Sheets for Files & Folders. | |

| M212S | 12 | 0.9 | High Clarity Containers, Household items,Injection Syringe, Laboratory products & ISBM Bottles |

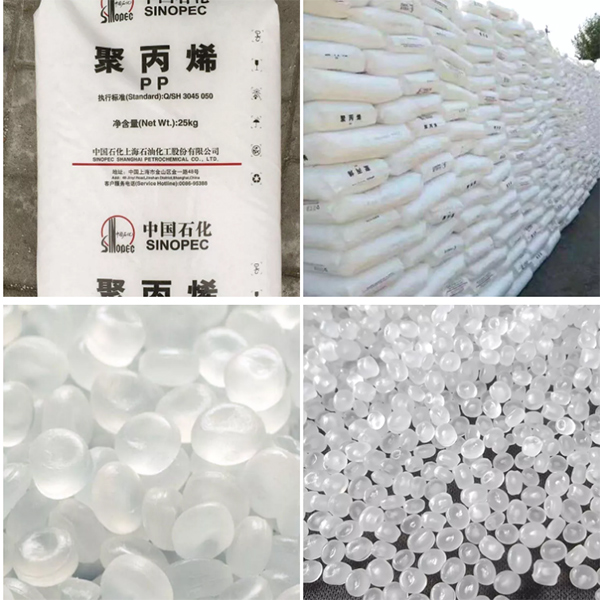

In 25kg bag, 16MT in one 20fcl without pallet or 26-28MT in one 40HQ without pallet or 700kg jumbo bag, 26-28MT in one 40HQ without pallet.

In 25kg bag, 16MT in one 20fcl without pallet or 26-28MT in one 40HQ without pallet or 700kg jumbo bag, 26-28MT in one 40HQ without pallet.